|

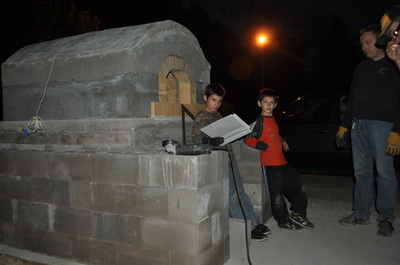

Today we broke into 2 work groups. One group worked on building another portion of the wall and cutting the blocks to place over the arches that are over the wood storage area. The other group started to stain the wood that will be used for the rafters and the roof. The groups where segregated by gender but the women didn’t complain since they were the ones doing the staining so they were able to be out of the rain and cold. The guys did a great job cutting the blocks with a curve to cover the arches and laying and leveling the blocks. When the work day was over we placed a piece of plywood over the front bricks so that there won’t be exposed edges when people where looking at the oven at Trunk or Treat that night. Each day that we work brings us a little closer to the finished project. The skills that have been learned in the past few months are astounding. Things like how to mix cement, how to lay and level block, the importance of reading the level correctly, how to use power tools, and how great my fellow workers are. I have been on mission trips where you travel a distance to help others and I have to say I am getting just as much satisfaction working on our own mission trip right here in Racine. I will never be a masonry worker and I don’t know that I will ever have the occasion to build a cement wall again but the memories and the skills will stay with me forever. I really encourage you to join us for a work day if you haven’t already done so. Our church may not have been affected by a hurricane, fire or other natural disaster but the community oven project can give you the same feeling of helping others and working together in a situation were you are all learning and sharing together. Halloween night our church hosted Trunk or Treat from 6 pm to 8 pm. The event was well attended and the fire in the oven brought awareness of the project to the people of our community. It was fun to see the flames in the oven. The smell of the fire added to the festive atmosphere of the evening. We had between 90 -100 kids and their families stop by the church parking lot to Trunk or Treat with us. The oven was quite the conversation piece. It was fun to hear people asking about when the bread baking would happen or asking for details about the construction process. The closer we get to completion the more excitement from the community there is. Please keep our project in your prayers. We hope that God will bless the oven and all those who are touched by it. Saturday 10/24: I have talked a lot about how cold the Saturday mornings have been but I would take anyone of those cold days for the wet rainy weather we had on Saturday. As much as we need the rain I wish it would come any time other than Saturday mornings. It was a reminder that our comfort is not what this project is about. We put the easy up tent up over the oven to protect the workers from the rain and to make it possible for us to the put the arches up and to start forming the outside walls around the oven. Nate & Jake learned how to use the blocks and lines to lay the block walls straight and even. Bob built the arches over the wood storage with the bricks that where donated by North Star Stone. He had Jeff cut the blocks that were needed to make the wall complete. By the time he was done cutting it looked like he had aged 15 years his hair was so grey. We joked that working with his boys was aging him quickly. Jeff & I appreciate everyone’s help with the oven but especially enjoy when both of our boys can be there to work on a work day because it gives our family a chance to volunteer our time together. Jake is gone to college and Nate is taking a college class that meets on Saturdays and works at least one weekend a month so being able to all be at a work day is a special time for our family. Tuesday 10/20: Tuesday nights are getting dark very early. This past week we planned for the brick arches over the wood storage area. Bob again offered to make the form at home. We also cleaned the supplies out of the entry way to the hall so it would be ready to be used on Friday. We had a few extra hands to help with the cleaning jobs.

Saturday 10/17: This morning the winter coats were brought out from the closet and the hot water and coffee were utilized by more than just the usual coffee drinkers. Today we poured the concrete walls over the top of the oven. Deb & Steve where manning the cement mixer and they couldn’t keep up with the skillful cement workers. It seemed like we would just get the cement mixed and in the buckets and the call for more mortar would come. We started the day with a truck bed full of buckets of mortar to be mixed and we used all but one. The correct recipe of water and mortar seemed to elude us at times but trial and error helped us get it correct by the end. In the pictures it looks like Tracy might be blessing the oven but she is actually dampening the mortar as Jeff & Charles smooth out the top layer. All hands that weren’t working with cement where utilized to pound on the wooden forms to help to get the air bubble out of the mortar as the next layer was added. We worked a longer day on the 10/17 so we took a lunch break with food that was supplied by Sandy, Norma, Bob & Tracy. We were all grateful for the meal and the fellowship that we shared. At the end of the day we had the 6 inches of concrete around the oven chamber. Saturday 10\10 started out chilly again. Most of us came wearing 3 layers so that we could shed them once the sun started to warm the day. We once again had to soak the bricks so that the mortar wouldn’t dry too quickly on the arch. Pulling the bricks out of the water was a little cold when we first got started. Even though we had carefully measured the arch, a little adjusting had to be done to get the bricks to fit correctly. Once the first arch was formed and given a chance to start to dry bricks were added between the smaller arch and the larger ones to bridge the gap. Steve & Jeff did the honors on the small arch and Karen & Deb tried their hand at placing the bricks on the adjoining one. I learned how patient you need to be with the process to make sure the angles are correct and there are no gaps. Once the bricks were placed we mortared across the tops of the bricks to form the bond between the 2 arches. The final project of the day was to build the wood forms around the oven that will hold the concrete when we pour the upper wall and clad around the top of the oven. The concrete will be 6 inches thick around the oven chamber. While we were marking the 6 inch height on the form we had to crawl on top of the arches that were built last week. I was a little concerned to be the one to be on the top of the arch because I didn’t want to be the one to make them fall. My trepidation was for naught as the arches held just fine while we moved around on them. One thing I am learning throughout the process of building the oven is that I need to have a stronger faith. From trusting in my fellow builders and my own skills to trusting that God is with us every step of the way and will help us be his hands and feet I have shown my doubting Thomas side. My fellow builders have been quick to point out that I need to have more faith and I like to think that besides learning new construction skills I am also working on my faith journey. I wouldn’t be able to do it without my fellow work crew members who are there with me every step of the way. We have had many discussions ranging from my doubting faith, to how God will use the oven in our community, and how hunting fits into God’s plan for the world. We have been able to share our time and faith with a few members of the community who have stopped by to chat or to help. Working on the oven has been a blessed experience and I hope that you will consider joining us for a work day. Tuesday 10/13 we will be starting at 6:30 and we will be cutting the rebar form for the top of the oven and laying the aluminum foil over the oven to form the protective layer between the bricks and the mortar that will surround them. Saturday 10/17 we will be pouring the mortar for the side walls and cladding the top of the oven with mortar. We will also be staining the wood that we milled in Wisconsin. We will be starting at 8 am and working until 3 or 4. Lunch will be provided so feel free to stop in and help out if you are available. Tuesday 10/6 we gathered once again to figure the measurements for the form for the small arch for the entry way. We have been putting our mathematical skills to the test figuring out the rise of the arch and making sure that the distance between the top of the small arch and the larger arch is correct. We also cut all of split bricks for the arch on Tuesday so that we would be ready to start on Saturday morning. We are happy that Terry Goldsmith had a wet saw that he is borrowing to us so we didn’t have to rent or purchase one. We were again using flash lights towards the end of the night to see what we were doing so Bob took the measurements and the wood and cut the form at his house so we weren’t cutting in the dark. Our first work day in October started out pretty cold but we all thought to dress in layers and as the sun did its work we were able to shed a layer of 2 and enjoy the beautiful day. Today is the day that could be very exciting or very frustrating as we are making the arches for the top of the oven. We started the day with a brief meeting about what the plan for the day was. The bricks had to be soaked in water before they could be buttered with mortar and placed on the form to make the arch. Soaking the bricks makes sure that the bricks don’t draw the moisture from the mortar to quickly letting it dry to fast. When we placed the brick on the form the bottoms of the bricks had to be touching each other at just the right angle in order for the arch to stay in tack once the form was removed as the mortar wouldn’t be dry yet. We all held our breath as the form was removed the first time, hoping that the bricks didn’t fall in a heap on the hearth floor. The first arch held and we moved on to the next one. One person laid the bricks on the form while 2 others (one on each side of the oven) made sure that the mortar was securely in between each of the brick and holding them in place as the next brick was placed. The rest of the crew was busy handling the bricks and cutting the angle in the bricks that started the arch on each side. After the form was removed from each arch the underside was wiped with a wet sponge to make sure that no excess mortar had seeped through. The fronts of the bricks were also wiped before the next arch was built to make sure that the brick fit snuggly against each other. We were making good progress on the arches and decided to break for lunch as a group and then continue with the arches until they were all complete. Frozen pizzas, chips & salsa, veggies & dip, drinks, and some sweets were brought in and we enjoyed our first pizza party inspired by the oven. The pizzas tasted fine but we are all looking forward to making them in the wood fire oven. After lunch we finished the final arches. The very last arch was only half the width of the rest of the arches so each brick had to be cut in half before they could be laid. Seeing the oven with the arches complete makes it obvious to those passing by what we are building. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

August 2016

Categories |

RSS Feed

RSS Feed